Electric power monitoring system

首页 > English > Solution > Electric power monitoring system >

Electric power control system

Electric power control system

Publish Date:2016-11-29 23:13 Viewed times: 作者:admin

Publish Date:2016-11-29 23:13 Viewed times: 作者:admin

Summary

SLM1200 power control system is a new generation of centralized control system designed and developed by SEPT software development and management system. The system adopts advanced object-oriented database, cross platform, modular technology, in line with international standards IEC61970, IEC61968, IEC61850 etc., comply with the design principles of integration, to provide a complete set of advanced electric power dispatching automation management system for power, petroleum chemical industry, non-ferrous metallurgy, transportation, public buildings and other fields.

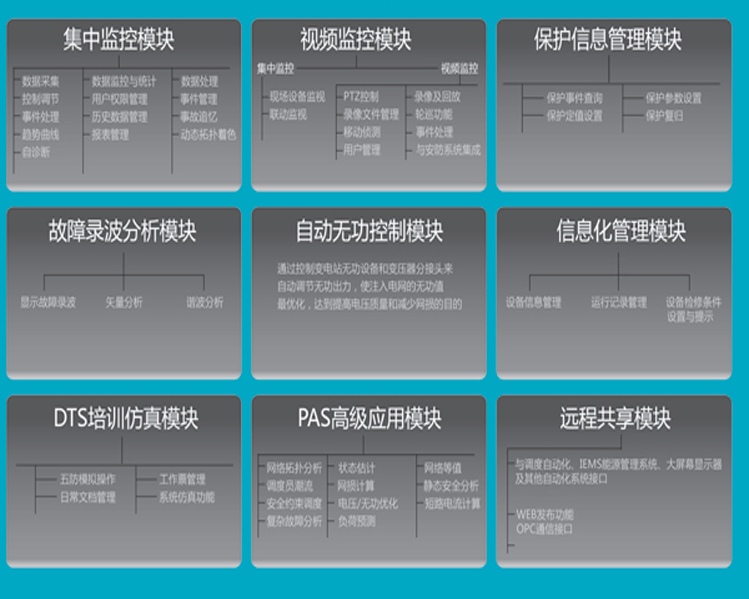

SLM1200 the company adhering to the centralized control system in power system protection, substation monitoring and control station and the successful experience of dispatching automation system, mainly integrates centralized monitoring, video monitoring, protection of information management, fault analysis, automatic reactive power control, information automation, DTS, PAS advanced applications, simulation training remote sharing, data security management module.

Major function

Automatic system for centralized monitoring and management of all substations in one or more areas.

The protection information management module includes the protection of the basic information, the protection of events, protection setting and the setting function.

SCADA system platform to achieve remote control, telemetry processing, the more limited judgment, calculation and other real-time monitoring functions.

Historical data service module, the realization of the historical data storage, management functions.

PAS advanced application module, to achieve network modeling, network topology, power flow analysis, short circuit calculation, state estimation, stability analysis and other functions.

Training Simulation Application module DTS, to achieve a variety of scheduling personnel operating skills and application skills training.

Fault record wave analysis module is not only a simple waveform display, but also includes the function of vector analysis;

Automatic reactive power control module optimizes reactive power compensation according to the strict reactive power control strategy to ensure the reactive power balance and voltage quality.

Power generation control AGC module, to achieve power generation unit startup and shutdown plans, automatic generation control and other functions.

The information automation module provides the powerful technical guarantee for the user's operation, maintenance, maintenance and daily management.

Security WEB module, the realization of the network control data release and security management functions.

Technical feature

The system uses the distributed professional power SCADA configuration software platform.

Support cross platform operating environment, including Windows2000/Vista/XP/WIN7/WIN8, LINUX, UNIX.

At the same time support 32 bit computers and 64 bit computer systems.

Object oriented and modular design concept, flexible configuration and function of the expansion.

Large scale database includes real-time database and history database, real-time database is classified database, and the database is a large commercial database, which supports Oracle, Sybase, SQLServer, MySQL.

The man-machine interface is friendly, and the 3D graphics based on OpenGL.

Dynamic coloring function, so that the operator of the power system equipment is charged, not charged, grounding and other state information at a glance.

Switch control optional with "five anti" lock control, programmable logic control.

Good open, easy to communicate with other systems, support for WEB release and mobile APP real-time browsing.

System built in high-level scripting language to facilitate the user secondary development and flexible application.

The embedded video monitoring module not only saves the investment, but also meets the requirements of the video surveillance system.

Application examples

Comprehensive solution of power control in petroleum and petrochemical industry

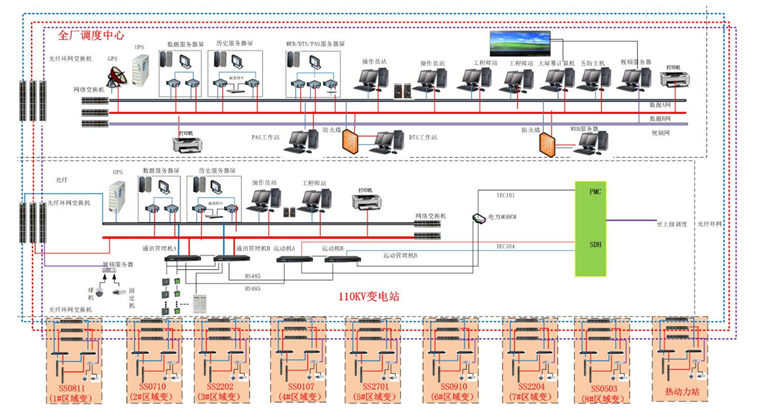

Large petrochemical plant power supply to take the regional management mode, voltage level is related to 110KV, 35KV, 10KV, 400V and other kinds , the number of variable power distribution stations, a wide range of geographical distribution, management is difficult. Kangbida experience of power monitoring project for nearly 20 years and the implementation of software development based on the combination of high reliable hardware products, provide reliable SLM1200 power control system of integrated solutions for the majority of users of petroleum and petrochemical.

SLM1200 electric control system adopts a distributed structure, the substation and control center by fiber ring network topology design, 35KV in each region separately set up regional centralized control system, centralized monitoring of each region, at the same time to upload data to the control center, to realize the whole range of operation of power equipment the on-line monitoring of power system, three level control, five control and dispatching automation function requirements. In order to lay a foundation for the standardization and automation of electric power operation and management of petrochemical enterprises, the management cost of enterprise is greatly reduced, the time of fault treatment is shortened, and the power efficiency is improved.

About SILIMIN

Company profile

Corporate culture

Technology R&D

Quality assurance

Social Policies

Enterprise honor

Contact US

Product

Satellite Synchronous Clock

Synchronous Time Display

Fire Monitor and Alarm Series

Security Evacuation & Broadcast

Power Monitor and Communication

Latest News

Company news

Industry news

Recruitment needs

Application performance

Data download

Engineering case

Power monitoring and communication case

Network time synchronization case

Time synchronization display case

Power plant time synchronization case

Case of fire alarm monitoring

Safety evacuation broadcast case

Pay attention to us

Chinese official website

English official website

Mailbox login

Taobao portal

Member login

Member registrationContact us

Telephone:+86(755)-88316675

SKPE 1:rocky-xiang

SKPE 2:Na Tong

Email:5332592@qq.com

Mobile phone:+86-18922834599

Website:www.silimin.com

Shenzhen silimin Power Automation Co., Ltd. Copyright © 2003 - 2016

SiLimin company Copyright Guangdong ICP 05019058

SiLimin company Copyright Guangdong ICP 05019058

Sitemap

Sitemap